RUBBER HOSE

LOW & MEDIUM PRESSURE HOSE

- PH253 - R1AT / 1SN

- PH243 - 1ST

- PH296 - 1SNX - HP

- PH244 - 2ST

- PH258 - 2SC

- PH297 - 2SNX - HP

- PH293 - R17

- PH213 - 3000 PSI

- PH214/224 - 4000 PSI

- PH215/225 - 5000 PSI

- PH216 - 6000 PSI

- PH142 - 2 WB - 09 Series

- PH276 - TRIFLEX

- PH245 - HYDRAULIC OIL S & D HOSE

- PH146 - R5

- PH186 - R5C XT

- PH250 - R3

- PH147 - R6

- PH204 - R6 FRAS MSHA

- PH261 - 1TE

- PH262 - 2TE

- PH263 - 3TE

- PH175 - JACK HOSE

- PH295 - R19

- PH299 - R2AT / 2SN - ABRAZON - X MSHA

- PH248 - R1AT / 1SN HARD - X MSHA

- PH298 - R1AT / 1SN ABRAZON - X MSHA

- PH553 - R1AT / 1SN LOW TEMPERATURE

- PH255 - R1AT / 1SN HIGH TEMPERATURE MSHA

- PH291 - R1AT / 1SN ULTRA HIGH TEMPERATURE MSHA

- PH208 - 1ST HARD - X MSHA

- PH557 - 1SC LOW TEMPERATURE

- PH267 - 1SC HIGH TEMPERATURE MSHA

- PH269 - 1SC ULTRA HIGH TEMPERATURE MSHA

- PH206 - 1SNX - HP ABRAZON - X MSHA

- PH237 - 1SNX - HP HIGH TEMPERATURE MSHA

- PH249 - R2AT / 2SN HARD - X MSHA

- PH554 - R2AT / 2SN LOW TEMPERATURE

- PH256 - R2AT / 2SN HIGH TEMPERATURE MSHA

- PH292 - R2AT / 2SN ULTRA HIGH TEMPERATURE MSHA

- PH209 - 2ST HARD - X MSHA

- PH230 - 2SC HARD - X MSHA

- PH260 - 2SC ABRAZON - X MSHA

- PH558 - 2SC LOW TEMPERATURE

- PH268 - 2SC HIGH TEMPERATURE MSHA

- PH270 - 2SC ULTRA HIGH TEMPERATURE MSHA

- PH207 - 2SNX - HP ABRAZON - X MSHA

- PH238 - 2SNX - HP HIGH TEMPERATURE MSHA

- PH198 - R17 HARD - X MSHA

- PH294 - R17 ABRAZON - X MSHA

- PH593 - R17 HIGH TEMPERATURE MSHA

- PH594 - R17 UTRA HIGH TEMPERATURE MSHA

- PH229 - R19 HARD - X MSHA

- PH222 - R19 ABRAZON - X MSHA

- PH223 - 3000 PSI HARD - X MSHA

- PH403 - 3000 PSI ABRAZON - X MSHA

- PH413 - 3000 PSI LOW TEMPERATURE

- PH406 - 6000 PSI HARD - X MSHA

- PH496 - 6000 PSI ABRAZON - X MSHA

- PH141 - R5R MSHA

- PH247 - R6 MSHA

- PH239 - 3TE CPE Rubber

- PH215 - JACK HOSE HARD - X MSHA

- PH404 - 4000 PSI HARD - X MSHA

- PH464 - 4000 PSI ABRAZON - X MSHA

- PH484 - 4000 PSI HARD - X MSHA

- PH494 - 4000 PSI ABRAZON - X MSHA

- PH226 - 5000 PSI HARD - X MSHA

- PH466 - 5000 PSI ABRAZON - X MSHA

- PH426 - 5000 PSI HARD - X MSHA

- PH486 - 5000 PSI ABRAZON - X MSHA

- PH433 - 3000 PSI HIGH TEMPERATURE MSHA

- PH453 - 3000 PSI ULTRA HIGH TEMPERATURE MSHA

- PH414 - 4000 PSI LOW TEMPERATURE

- PH434 - 4000 PSI HIGH TEMPERATURE MSHA

- PH454 - 4000 PSI ULTRA HIGH TEMPERATURE

- PH415 - 5000 PSI LOW TEMPERATURE

- PH435 - 5000 PSI HIGH TEMPERATURE MSHA

- PH455 - 5000 PSI ULTRA HIGH TEMPERATURE MSHA

- PH416 - 6000 PSI LOW TEMPERATURE

- PH436 - 6000 PSI HIGH TEMPERATURE MSHA

- PH456 - 6000 PSI ULTRA HIGH TEMPERATURE MSHA

- PH271 - 1TE HIGH TEMPERATURE MSHA

- PH272 - 2TE HIGH TEMPERATURE MSHA

- PH273 - 3TE HIGH TEMPERATURE MSHA

- PH185 - HYDRAULIC OIL S & D HOSE HIGH TEMPERATURE MSHA

- PH164 - R6 HIGH TEMPERATURE MSHA

- PH264 - R6 HIGH TEMPERATURE MSHA

- PH227 - R6 ULTRA HIGH TEMPERATURE MSHA

- PH507 - 2SNX - HP LOW TEMPERATURE

- PH460 ROCKDRILL

- PH461 HEAVY DUTY AIR DRILL HOSE

- PH120 FIRE ENGINE BOOSTER HOSE

- PH401 OIL AND COMPRESSED AIR HOSE

- PH431 TITAN GENERAL AIR/WATER - 500 PSI MSHA

- PH125 - JACK HOSE HARD - X MSHA

- PH254 - R2AT / 2SN

- PH257 - 1SC

- PH290 - PILOT HOSE

- PH402 - CSM- OIL & COMPRESSED AIR HOSE

- PH573 - R1AT / 1SN ULTRA HIGH TEMPERATURE MSHA

- PH438 PUSH LOK HOSE MSHA

- PH130 - R3 TEMP MASTER MSHA

- PH27X - MADMAX POWER STEERING HOSE

- PH2GC - POWER STEERING PRESSURE HOSE

- PH597 - 2SNX - HP HARD-X MSHA

- PH109 - TRACK SAFE - TRIFLEX

- PH112 - TRACK SAFE - R17

- PH115 - TRACK SAFE - RAT / 1SN

- PH122 - TRACK SAFE - R2AT / 2SN

- PH181 - TRACK SAFE - R4

- PH210 - TRACK SAFE - 1SC

- PH102 - TRACK SAFE - R6

- PH104 - TRACK SAFE - 2SNX - HP

- PH139 - TRACK SAFE - 1SNX - HP

- PH211 - TRACK SAFE - 2SC

- PH189 - R5 XT

- PH405 - Engine and Air Brake Hose

- PH231 - MADMAX R1AT/1SN

PRESSURE WASHER HOSE

HIGH PRESSURE SPIRAL HOSE

- PH177 - SAE 100 R12

- PH178 - R13

- PH279 - R15

- PH277 - 4SP

- PH278 - 4SH

- PH183 - FIRE SHIELD HOSE

- PH187 - SAE 100 R12 HARD - X MSHA

- PH285 - SAE 100 R12 ABRAZON - X MSHA

- PH128 - R13 HARD - X MSHA

- PH259 - R15 ABRAZON - X MSHA

- PH219 - 4SP HARD - X MSHA

- PH205 - 4SP ABRAZON - X MSHA

- PH220 - 4SH HARD - X MSHA

- PH289 - 4SH ABRAZON - X MSHA

- PH111 - TRACK SAFE - 4SP

- PH134 - TRACK SAFE - R15

- PH124 - TRACK SAFE - 4SH

- PH132 - TRACK SAFE - R12

- PH133 - TRACK SAFE - R13

WATER BLAST HOSE

MINING HOSE

FUEL HOSE

AUTOMOBILE & AIR CONDITIONING

- PH440 - COMPRESSED AIR WIRE BRAIDED HOSE

- PH471 - STEAM 1 W/B

- PH472 - STEAM 2 W/B

- PH475 - STEAM HOSE WITH HELICAL WIRE

- PH555 - NON CONDUCTIVE CARBON FREE HOSE

- PH566 - AIR BREATHING HOSE

- PH601 - WATER SUCTION & DISCHARGE HOSE W.P. 10 BAR

- PH602 - WATER DISCHARGE HOSE W.P. 10 BAR - LAY FLAT

- PH604 - WATER SUCTION & DISCHARGE HOSE W.P. 20 BAR

- PH606 - STEEL MILL WATER DELIVERY HOSE WITH FIBER GLASS COVER

- PH607 - STEEL MILL WATER SUCTION AND DELIVERY HOSE WITH FIBER GLASS COVER

- PH609 - THERMOPLASTIC LINED PAINT S & D HOSE 10 BAR

- PH610 - WATER DISCHARGE HOSE - W.P. 20 BAR

- PH611 - OIL / FUEL SUCTION & DISCHARGE HOSE W.P. 10 BAR

- PH613 - OIL / FUEL DELIVERY HOSE W.P. 10 BAR

- PH614 - OIL SUCTION & DISCHARGE HOSE W.P. 20 BAR

- PH615 - OIL SUCTION & DISCHARGE HOSE - 40 BAR

- PH617 - OIL FUEL DELIVERY HOSE - 20 BAR

- PH620 - AIR & WATER DISCHARGE HOSE - 10 BAR

- PH621 - CEMENT / PLASTER PLACEMENT HOSE

- PH622 - HIGH PRESSURE PLASTER SPRAY HOSE

- PH623 - BULKMATERIAL SUCTION AND DISCHARGE HOSE W.P. 10 BAR

- PH624 - SHOT BLASTING HOSE W.P. 12 BAR - PH2

- PH625 - BUNKER TRUCK HOT AIR BLOWER HOSE W.P. 10 BAR

- PH626 - DRY CEMENT DELIVERY / SILO HOSE

- PH628 - ABRASIVE BULK MATERIAL SUCTION AND DISCHARGE HOSE W.P 20 BAR

- PH629 - ABRASIVE BULK MATERIAL DISCHARGE HOSE W.P 10 BAR

- PH630 - AIR & WATER DISCHARGE HOSE - 20 BAR

- PH631 - INDUSTRIAL DUTY AIR HOSE W.P. 20 BAR

- PH639 - BULKMATERIAL DISCHARGE - 20 BAR

- PH642 - XLPE CHEMICAL SUCTION AND DISCHARGE HOSE W.P. 17 BAR

- PH645 - UHMPE CHEMICAL SUCTION & DISCHARGE HOSE

- PH646 - EPDM CHEMICAL SUCTION & DISCHARGE HOSE

- PH647 - SLURRY & MUD WATER SUCTION AND DISCHARGE HOSE

- PH648 - UHMWPE SUCTION & DISCHARGE HOSE FOOD

- PH649 - CONCRETE DELIVERY HOSE

- PH651 - RADIATOR HOSE

- PH657 - OIL FUEL DELIVERY HOSE FRAS - 20 BAR

- PH661 - MINE BLAST HANDLING HOSE - W.P. 20 BAR

- PH663 - AIR & WATER DISCHARGE HOSE FRAS - 20 BAR

- PH681 - SATURATED STEAM & HOT WATER HOSE

- PH687 - MULTI PURPOSE HOSE

- PH693 - FIRE SHIELD HOSE

- PH242 - FIRE SUPPRESSION HOSE

- PH684 - SHOT BLASTING HOSE W.P. 12 BAR

- PH690 - AVIATION FUEL HOSE

- PH695 - STEAM HOSE

- PH441 - COMPRESSED AIR WIRE BRAIDED HOSE MSHA

- PH482 - STEAM 2 W/B

- PH640 - EPDM WATER SUCTION & DISCHARGE HOSE W.P. 10 BAR

- PH674 - SHOT BLASTING HOSE W.P. 12 BAR - PH1 (PREMIUM ABRASION)

- PH61A LOW TEMPERATURE OIL SUCTION & DISCHARGE HOSE W.P. 10 BAR

- PH517 - PW 4K - 2TB

- PH202 - MINE SPRAY HOSE MSHA

- PH699 - OIL/FUEL DISCHARGE HOSE WP 30 BAR

- PH665 - RIG SUPPLY - FUEL/LIQUID MUD SUCTION & DISCHARGE HOSE W.P. 20 BAR

- PH6E0 - SLURRY/MUD SUCTION AND DISCHARGE HOSE W.P 10 BAR

THERMOPLASTIC HOSE

- PH148 - MEDIUM PRESSURE HYDRAULIC HOSE - R7

- PH149 - HIGH PRESSURE HYDRAULIC HOSE - R8

- PH194 - LOW TEMPERATURE - R18

- PH348 - MEDIUM PRESSURE HYDRAULIC HOSE - 1WB

- PH349 - HIGH PRESSURE HYDRAULIC HOSE - 2WB

- PH353 - HIGH PRESSURE HYDRAULIC HOSE - R8 (2PB)

- PH358 - R7 COMPACT HOSE

- PH761 - HYBRID HOSE - 1W

- PH762 - HYBRID HOSE - 2W

- PH151 - MEDIUM PRESSURE HYDRAULIC HOSE - R7 (NON CONDUCTIVE)

- PH152 - HIGH PRESSURE HYDRAULIC HOSE - R8 (NON CONDUCTIVE)

- PH195 - LOW TEMPERATURE - R18 (NON CONDUCTIVE)

- PH357 - HIGH PRESSURE HYDRAULIC HOSE - R8 (2PB) - NON CONDUCTIVE

- PH333 -LIQUEFIED PETROLEUM GAS HOSE

- PH704 SERIES

- PH1003 - PTFE - CONVOLUTED HOSE

SEWER JETTING HOSE

PAINT SPRAY HOSE

- PH340 - PAINT & AGGRESSIVE CHEMICAL SPRAY - 2W

- PH341 - PAINT & AGGRESSIVE CHEMICAL SPRAY - 1W

- PH342 - PAINT SPRAY - 1W

- PH343 - PAINT SPRAY - 2W

- PH344 / PH345 - HIGH PRESSURE PAINT SPRAY

- PH346 - VERY HIGH PRESSURE PAINT SPRAY

- PH347 - SUPER HIGH PRESSURE PAINT SPRAY

- PH721 / PH722 - FLUOROPOLYMER - LOW PRESSURE CONDUCTIVE / NON - CONDUCTIVE

- PH727 / PH728 - LOW PRESSURE CONDUCTIVE / NON - CONDUCTIVE

- PH729 / PH730 - LOW PRESSURE CONDUCTIVE / NON - CONDUCTIVE

HIGH PRESSURE HOSE

AIR BREATHING HOSE

LUBRICATION

CNG

REFRIGERATION

MICRO BORE

PILOT LINE

MOISTURE BLOK HOSE

PU DUCT

- PH179 - R14

- PH311 - (ELECTRICAL CONDUCTIVE) - R14

- PH313 - R14 INCREASED WALL

- PH370 - PTFE - CONVOLUTED HOSE

- PH371 - PTFE - ELECTRICAL CONDUCTIVE CONVOLUTED HOSE

- PH381 - R14 2W

- PH382 - PTFE GAS HOSE

- PH765 - MEDIUM PRESSURE FLUORO - COMP HOSE

- PH775 - GAS HOSE - ARAMID

- PH776 - GAS HOSE - 1W

- PH777 - BRAKE FLUID HOSE

- PH778 - NITROGEN GAS HOSE

- PH782 - CONVOLUTED PTFE HOSE WITH HELIX WIRE AND STAINLESS STEEL STANDARD WALL

- PH783 - CONVOLUTED PTFE HOSE WITH HELIX WIRE AND POLYPROPYLENE YARN STANDARD WALL

- PH785 - CONVOLUTED PTFE HOSE WITH POLYPROPYLENE YARN - STANDARD WALL

- PH779 - MEDIUM PRESSURE HOSE

- PH1570 - HIGH PRESSURE PTFE HOSE (D-PAC BRAID DESIGN)

- PH375 - TAPE WRAPPED ELECTRICAL CONDUCTIVE CONVOLUTED HOSE

- PH372 - TAPE WRAPPED CONVOLUTED HOSE

- PH374 - PTFE - CONVOLUTED HOSE 2W

- PH331 - PTFE HOSE WITH POLYESTER BRAID

- PH1003 - PTFE - CONVOLUTED HOSE

- PH902 - 2 SPIRALS OF HIGH TENSILE STEEL WIRE

- PH902P - 2 SPIRALS OF HIGH TENSILE STEEL WIRE, 1 BRAID OF STEEL WIRE

- PH902Q / PH902QL / PH902QZ - 4 SPIRALS OF HIGH TENSILE STEEL WIRE, 2 DENSE AND 2 OPEN LAYERS

- PH903 - 2 SPIRALS OF HIGH TENSILE STEEL WIRE, 1 BRAID OF G.I STEEL WIRE

- PH904 - 4 SPIRALS OF HIGH TENSILE STEEL WIRE

- PH904R - 4 SPIRALS OF HIGH TENSILE STEEL WIRE

- PH906 - 6 SPIRALS OF HIGH TENSILE STEEL WIRE

- PH906R - 6 SPIRALS OF HIGH TENSILE STEEL WIRE

- PH908 - 8 SPIRALS OF HIGH TENSILE STEEL WIRE

- PH906RR - 6 SPIRALS OF HIGH TENSILE STEEL WIRE

- PH902R - 2 SPIRALS OF HIGH TENSILE STEEL WIRE

COMPOSITE HOSE

- PH801 - POLY - TANKER HOSE

- PH802 - POLY - OIL HOSE

- PH803 - POLY - AVIATION FUEL COMPOSITE HOSE

- PH804 - POLY - FUEL HOSE

- PH805 - POLY - PTFE CHEMICAL

- PH806 - POLY - CHEMICAL-SS

- PH807 - POLY - CHEMICAL HOSE - P P

- PH809 - POLY - DOCK PTFE

- PH810 - POLY - DOCK PG HOSE

- PH811 - POLY - OIL DOCK HOSE

- PH817 - POLY - BITUMEN TRANSFER HOSE

- PH814 - POLY - CHEMICAL-SG

- PH812 - POLY - LIGHT WEIGHT FUEL HOSE - AG

- PH813 : POLY - CHEMICAL HOSE - PS

- PH815 : POLY - CHEMICAL HOSE - PS

- PH816 : POLY - VAPOUR RECOVERY HOSE - GG

- PH808 - POLY - CHEMICAL DOCK HOSE

- PH818 - POLY - CHEMICAL HEAVY DUTY HOSE - SS PTFE

- PH819 - POLY - CHEMICAL HEAVY DUTY HOSE - SG

SS CORRUGATED

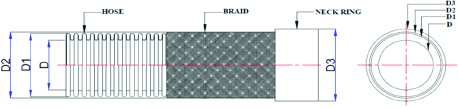

PH 2100 SERIES - MFM SPECIAL

Structure Annular corrugated Mechanical formed flexible metal hoses produced from longitudinally welded tubes with or without braiding

Characteristics Light Weight / Medium Flexibility

Standards EN ISO 10380

Hose Material Stainless Steel AISI 304, AISI 321, AISI 316L

Braiding Material Stainless Steel AISI 304 and AISI 316L

Suitable Fittings Types Threaded end, Flange end, Pipe end etc as per customer specifications

Note: Please Contact our sales team for Specific Length

METRIC SYSTEM :

| Item Code | DN |

Tube ID

|

Tube OD

|

Braid OD

|

Tol

|

Braid

|

BR/r

|

WP

|

BP

|

W

|

|||

| (D) | (D1) | (D2) | (Dx) | Coverage | Static | Dynamic | SWB* W.P (Max) |

DWB W.P (Max) |

SWB B.P (Min) |

SWB Weight |

DWB Weight |

||

| mm | mm | mm | mm | % | mm | mm | bar | bar | bar | Kg/m | Kg/m | ||

| R006MFMSR10 | 6 | 6.3 | 9.6 | 10.8 | ± 0.25 | 94 | 25 | 110 | 162 | 194.4 | 648 | 0.16 | 0.24 |

| R008MFMSR10 | 8 | 8.5 | 12.1 | 13.6 | ± 0.25 | 92 | 32 | 130 | 114 | 137 | 456 | 0.20 | 0.30 |

| R010MFMSR10 | 10 | 10 | 14.1 | 15.7 | ± 0.25 | 92 | 38 | 150 | 110 | 132 | 440 | 0.22 | 0.34 |

| R012MFMSR10 | 12 | 12.1 | 16.7 | 18.2 | ± 0.25 | 92 | 45 | 165 | 89 | 107 | 356 | 0.25 | 0.39 |

| R016MFMSR10 | 16 | 16.6 | 21.9 | 23.5 | ± 0.25 | 96 | 58 | 195 | 80 | 96 | 320 | 0.40 | 0.61 |

| R020MFMSR10 | 20 | 20.2 | 26.7 | 28.2 | ± 0.25 | 94 | 70 | 225 | 70 | 84 | 280 | 0.53 | 0.78 |

| R025MFMSR10 | 25 | 25.3 | 32.3 | 34.2 | ± 0.30 | 96 | 85 | 260 | 58 | 70 | 232 | 0.76 | 1.16 |

| R032MFMSR10 | 32 | 33.6 | 41.2 | 43 | ± 0.30 | 94 | 105 | 300 | 46 | 56 | 184 | 1.04 | 1.55 |

| R040MFMSR10 | 40 | 40 | 49.5 | 51.3 | ± 0.30 | 92 | 130 | 340 | 42 | 52 | 168 | 1.32 | 1.94 |

| R050MFMSR10 | 50 | 50.4 | 60.7 | 63 | ± 0.30 | 96 | 160 | 390 | 38 | 48 | 152 | 1.78 | 2.68 |

NOTE:

1. Test Pressure is 1.5 times of Working Pressure @ 20°C.

2. SWB - Single Wire Braid, DWB - Double Wire Braid, WP - Working Pressure, BP - Burst Pressure.

3. Contact Factory for Temperature correction Factor.

4. THESE INFORMATIONS ARE FOR GUIDANCE ONLY, WE RESERVE THE RIGHT TO ALTER (OR) AMEND SPECIFICATIONS AS DEEMED NECESSARY.

5. General Tolerance is applicable.

)

IMPERIAL SYSTEM :

| Item Code | DN | Braids | Braid Construction (No of Carriers X No od Strands X Wire Diameter) |

Braid

|

ID

|

OD

|

WP

|

BP

|

BR/r

|

W

|

|

| Coverage | (D) | (D1 & D2) | W.P (Max) 70°F | B.P (Max) 70°F | Dynamic | Static | Weight per Foot | ||||

| % | inch | inch | psi | psi | inch | inch | lbs | ||||

| R006MFMS000 | 1/4" | 0 | 24 X 5 X 0.012 | 94 | 0.25 | 0.38 | 72 | --- | 4.33 | 0.98 | 0.05 |

| R006MFMSR10 | 1/4" | 1 | 24 X 5 X 0.012 | 94 | 0.25 | 0.43 | 2370 | 9480 | 4.33 | 0.98 | 0.11 |

| R006MFMSR20 | 1/4" | 2 | 24 X 5 X 0.012 | 94 | 0.25 | 0.47 | 2844 | 11376 | 4.33 | 0.98 | 0.16 |

| R008MFMS000 | 5/16" | 0 | 24 X 6 X 0.012 | 92 | 0.34 | 0.48 | 72 | --- | 5.12 | 1.26 | 0.06 |

| R008MFMSR10 | 5/16" | 1 | 24 X 6 X 0.012 | 92 | 0.34 | 0.54 | 1650 | 6600 | 5.12 | 1.26 | 0.13 |

| R008MFMSR20 | 5/16" | 2 | 24 X 6 X 0.012 | 92 | 0.34 | 0.58 | 1980 | 7920 | 5.12 | 1.26 | 0.20 |

| R010MFMS000 | 3/8" | 0 | 24 X 7 X 0.012 | 92 | 0.39 | 0.56 | 72 | --- | 5.91 | 1.50 | 0.07 |

| R010MFMSR10 | 3/8" | 1 | 24 X 7 X 0.012 | 92 | 0.39 | 0.62 | 1600 | 6400 | 5.91 | 1.50 | 0.15 |

| R010MFMSR20 | 3/8" | 2 | 24 X 7 X 0.012 | 92 | 0.39 | 0.67 | 1920 | 7680 | 5.91 | 1.50 | 0.23 |

| R012MFMS000 | 1/2" | 0 | 24 X 8 X 0.012 | 92 | 0.48 | 0.66 | 65 | --- | 6.50 | 1.77 | 0.07 |

| R012MFMSR10 | 1/2" | 1 | 24 X 8 X 0.012 | 92 | 0.48 | 0.72 | 129 | 5160 | 6.50 | 1.77 | 0.17 |

| R012MFMSR20 | 1/2" | 2 | 24 X 8 X 0.012 | 92 | 0.48 | 0.76 | 1548 | 6192 | 6.50 | 1.77 | 0.26 |

| R016MFMS000 | 5/8" | 0 | 36 X 8 X 0.012 | 96 | 0.65 | 0.86 | 65 | --- | 7.68 | 2.28 | 0.12 |

| R016MFMSR10 | 5/8" | 1 | 36 X 8 X 0.012 | 96 | 0.65 | 0.93 | 1160 | 4640 | 7.68 | 2.28 | 0.27 |

| R016MFMSR20 | 5/8" | 2 | 36 X 8 X 0.012 | 96 | 0.65 | 0.97 | 1332 | 5568 | 7.68 | 2.28 | 0.41 |

| R020MFMS000 | 3/4" | 0 | 36 X 9 X 0.012 | 94 | 0.80 | 1.05 | 43 | --- | 8.86 | 2.76 | 0.18 |

| R020MFMSR10 | 3/4" | 1 | 36 X 9 X 0.012 | 94 | 0.80 | 1.11 | 1015 | 4060 | 8.86 | 2.76 | 0.35 |

| R020MFMSR20 | 3/4" | 2 | 36 X 9 X 0.012 | 94 | 0.80 | 1.16 | 1218 | 4872 | 8.86 | 2.76 | 0.52 |

| R025MFMS000 | 1" | 0 | 36 X 9 X 0.016 | 96 | 1.00 | 1.27 | 43 | --- | 10.24 | 3.35 | 0.24 |

| R025MFMSR10 | 1" | 1 | 36 X 9 X 0.016 | 96 | 1.00 | 1.35 | 840 | 3360 | 10.24 | 3.35 | 0.51 |

| R025MFMSR20 | 1" | 2 | 36 X 9 X 0.016 | 96 | 1.00 | 1.39 | 1008 | 4032 | 10.24 | 3.35 | 0.78 |

| R032MFMS000 | 1 1/4" | 0 | 48 X 8 X 0.016 | 94 | 1.32 | 1.62 | 43 | --- | 11.81 | 4.13 | 0.36 |

| R032MFMSR10 | 1 1/4" | 1 | 48 X 8 X 0.016 | 94 | 1.32 | 1.69 | 665 | 2660 | 11.81 | 4.13 | 0.70 |

| R032MFMSR20 | 1 1/4" | 2 | 48 X 8 X 0.016 | 94 | 1.32 | 1.76 | 798 | 3192 | 11.81 | 4.13 | 1.04 |

| R040MFMS000 | 1 1/2" | 0 | 48 X 9 X 0.016 | 92 | 1.58 | 1.95 | 28 | --- | 13.39 | 5.12 | 0.47 |

| R040MFMSR10 | 1 1/2" | 1 | 48 X 9 X 0.016 | 92 | 1.58 | 2.02 | 605 | 2420 | 13.39 | 5.12 | 0.86 |

| R040MFMSR20 | 1 1/2" | 2 | 48 X 9 X 0.016 | 92 | 1.58 | 2.08 | 726 | 2904 | 13.39 | 5.12 | 1.25 |

| R050MFMS000 | 2" | 0 | 48 X 9 X 0.020 | 96 | 1.98 | 2.39 | 28 | --- | 15.35 | 6.30 | 0.59 |

| R050MFMSR10 | 2" | 1 | 48 X 9 X 0.020 | 96 | 1.98 | 2.48 | 550 | 2200 | 15.35 | 6.30 | 1.20 |

| R050MFMSR20 | 2" | 2 | 48 X 9 X 0.020 | 96 | 1.98 | 2.54 | 660 | 2640 | 15.35 | 6.30 | 1.80 |

NOTE:

1. Test Pressure is 1.5times of Working Pressure @ 70°F.

2. WP - Working Pressure, BP - Burst Pressure.

3. Contact Factory for Temperature correction Factor.

4. THESE INFORMATIONS ARE FOR GUIDANCE ONLY, WE RESERVE THE RIGHT TO ALTER (OR) AMEND SPECIFICATIONS AS DEEMED NECESSARY

5. General Tolerance is applicable.